Introduction

The emergence of 3D printing, also known as additive manufacturing, has revolutionized traditional manufacturing processes. This article explores the transformative impact of 3D printing on manufacturing, reshaping how products are designed, prototyped, and produced.

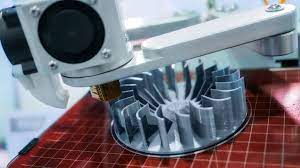

Additive Manufacturing: The Core Principle of 3D Printing

At the heart of 3D printing is additive manufacturing, where objects are constructed layer by layer. This technology utilizes a diverse range of materials, offering flexibility and precision that surpasses traditional manufacturing methods.

Prototyping and Rapid Prototyping in Product Development

3D printing accelerates product development cycles through rapid prototyping. This reduces costs, shortens timelines, and enhances design flexibility, allowing for quick iterations and improvements in the product development phase.

Customization and Personalization in Manufacturing

The ability to tailor products to individual needs is a hallmark of 3D printing. This technology meets the demands of niche markets and plays a crucial role in the rise of mass customization, offering unique and personalized products at scale.

Reducing Material Waste and Environmental Impact

Additive manufacturing minimizes material waste compared to traditional subtractive methods. The efficient utilization of materials contributes to sustainability, making 3D printing an eco-friendly alternative in manufacturing.

Complex Geometries and Intricate Designs

3D printing surpasses the limitations of traditional manufacturing, enabling the creation of complex and intricate structures. This capability opens up new design possibilities across various industries, from aerospace components to artistic creations.

Supply Chain Resilience and On-Demand Manufacturing

3D printing reduces dependence on traditional supply chains by enabling on-demand production and local manufacturing. This enhances supply chain resilience, allowing for increased flexibility in response to market changes and demands.

Medical Applications and Bioprinting

In the medical field, 3D printing has transformative applications. From customized medical devices to bioprinting for tissue engineering and organ transplants, this technology is revolutionizing healthcare, offering innovative solutions and improving patient outcomes.

- Aerospace and Automotive Innovations

Industries such as aerospace and automotive benefit from 3D printing with lightweight components and customized parts. This technology streamlines production processes, leading to advancements in performance, efficiency, and design flexibility.

Challenges in 3D Printing Technology

Despite its numerous advantages, 3D printing faces challenges, including speed and scalability concerns, ensuring consistent quality, and addressing material limitations. Ongoing research and innovation aim to overcome these hurdles.

Educational and DIY Applications of 3D Printing

Accessible prototyping empowers education and DIY projects through 3D printing. This technology fosters creativity, innovation, and hands-on learning experiences, contributing to the growth of the maker community.

Economic Impacts and Job Evolution

Widespread adoption of 3D printing brings economic implications and job evolution. While there may be concerns about job displacement, the technology also creates new opportunities and skill sets, contributing to a dynamic job landscape.

Regulatory and Intellectual Property Considerations

The growing use of 3D-printed products necessitates navigating regulatory frameworks and addressing intellectual property challenges. Balancing innovation with ethical and legal considerations is crucial in ensuring responsible use of the technology.

Investments and Industry Adoption of 3D Printing

Increasing investments in 3D printing technologies underscore its potential across industries. From healthcare to manufacturing, diverse sectors are adopting 3D printing, and emerging trends suggest continued growth and integration.

Conclusion

In conclusion, 3D printing has profoundly impacted manufacturing, offering unparalleled advantages in design flexibility, sustainability, and customization. As the technology continues to evolve, its integration into diverse sectors promises a future where 3D printing plays a central role in reshaping how we conceive, design, and produce products.